Repair and restoration

- Restoration of support units of rotary kilns and drying drums, mechanical treatment of the surface of rollers and bandages

- Restoration of trunnions and contact surfaces of support rollers (surfacing and grinding)

- Mechanical adjustment (installation in design and operational position)

- Sanding and surfacing of metal to recover the geometry

- The complex of services on restoration of shaft-pinion seats in case of a reducer

- Repair, restoration and modernization of dust-gas cleaning and aspiration systems

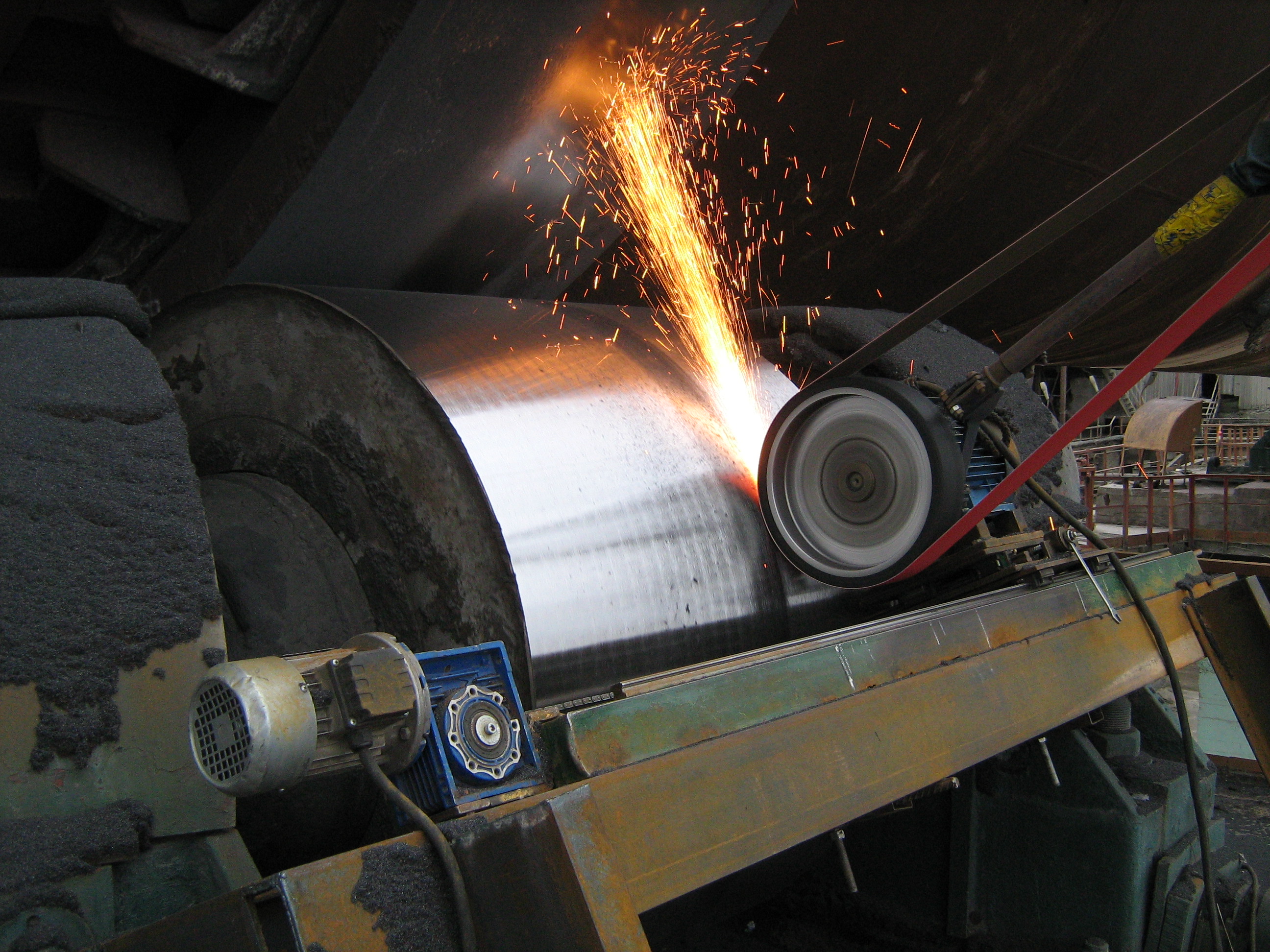

Mechanical adjustment (installation in design and operational position), machining of the working surfaces of the support rollers without dismantling

This method is based on a high-tech grinding process for restoring the geometric accuracy of contact surfaces.

Restoration is performed on modern portable equipment. The main advantage of this technology is the capability to perform restoration during rotation of the kiln, without interrupting its operation.

Main defects in operation:

- Wear and damage to the bearing surfaces of rollers and bandages;

- Bad attachment of the crown gears and bandages to the kiln shells (debarking drum);

- Formation of cracks in the kiln shell and sub-bandage plates;

- Bad contact of support surfaces of rollers and bandages;

- Skews in support units: axes of support rollers and drive gears relative to the kiln axis;

- Vibration of the kiln (drum) shell;

- Deviation of the slope of the frames of the support rollers and drive gears.

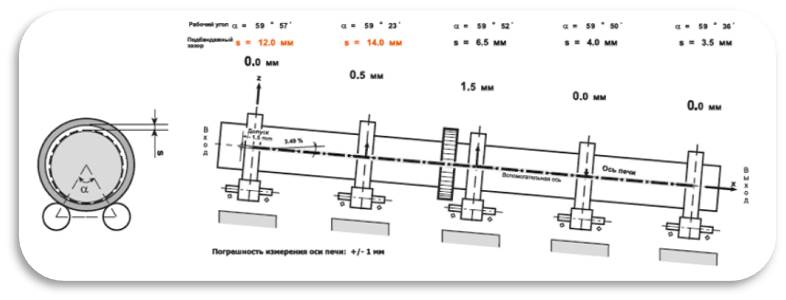

If these defects are found, the support nodes are restored at the site of their installation (without dismantling) followed by adjustment and mechanical configuration of the units. In accordance with the company's technology, we provide diagnostics of bandages, rollers, kiln shell (drum) with measurement of non-linearity, runout, hardness and roughness of working surfaces, check the position of the kiln (or drum) axis, position of the axes of support rollers and drive gear relative to the kiln axis, slopes of the frames of support rollers and drive gears.

Mechanical adjustment (installation in design and operational position)

It is performed:

- before the next routine or major repairs;

- after the next major or unscheduled repairs associated with the replacement of tires, rollers, shells, lining, crown gear, rectification of the non-rectilinearity of the kiln shell ot drum axis;

- after elimination of defects on the contact surfaces of the bandages and support rollers of the unit.